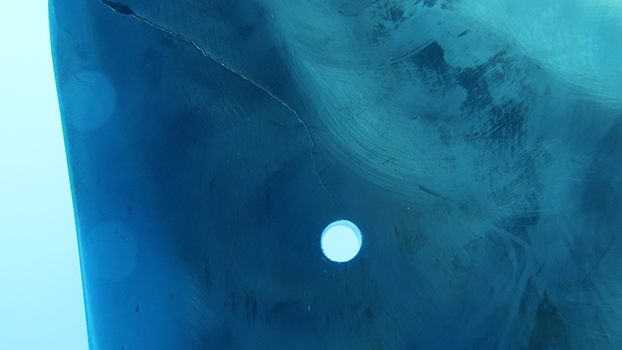

Immersub was contacted by a technical superintendent of a cargo vessel who reported to experience major vibration in the engine room. The suspected cause of the vibration was a defect on the propulsion of the vessel. Upon arrival at Port Louis anchorage, the dive team carried out the damage assessment of the stern part and found two blades’ trailing edge buckled. This damage has caused major cracks on the propeller blades.

The dive plan was discussed with Technical Superintendent, Master and Chief Engineer and based on the tight vessel schedule, it was decided to carry out temporary repairs to prevent further vibration and damage to the propeller. The dive team then proceeded with the drilling of arrest holes in the blades to prevent extension of the crack. After drilling the arrest holes, the leading edge was straighten in order to avoid further vibration. After the repairs, the vessel was able to sail back and no more vibration was experienced in the engine room.